Workforce management is a critical component of enterprise resource planning (ERP) systems, particularly for organizations that provide maintenance services for physical products installed at customer premises. This domain extends beyond general employee management and focuses on a subset of employees responsible for service and maintenance operations. Effective workforce management ensures that maintenance tasks—both routine and emergency—are executed efficiently, minimizing downtime and optimizing resource allocation.

ERP systems integrate various business functions, including workforce management. These systems categorize core functionalities into operational, administrative, and executive components. Workforce management falls under the operational category, particularly for manufacturing companies and service providers with distributed maintenance teams. An essential extension of ERP in this context is Customer Relationship Management (CRM), which facilitates tracking customer service interactions and managing service requests.

Traditionally, industries such as elevator manufacturing have pioneered workforce management implementation, setting standards for service efficiency and resource allocation. Similarly, utility companies—such as internet service providers and electrical grid operators—employ workforce management to coordinate field technicians who must physically visit customer locations for service installation, troubleshooting, or maintenance.

Maintenance Categories in Workforce Management

Effective workforce management requires a structured approach to handling different types of maintenance activities. These can be categorized into routine maintenance and emergency maintenance, each of which presents distinct challenges in scheduling, resource allocation, and cost optimization.

Routine Maintenance

Definition

Routine maintenance refers to pre-planned and scheduled interventions that prevent unexpected failures.

A common example is automobile servicing, where periodic oil changes help maintain engine performance and prevent breakdowns. In an industrial setting, routine maintenance is essential for extending the lifespan of machinery, reducing long-term repair costs, and maintaining operational efficiency.

From a technical perspective, routine maintenance follows a structured workflow:

Steps

- Scheduling: Organizations use ERP systems to determine optimal maintenance schedules based on equipment usage and historical failure data.

- Resource Planning: Required spare parts and tools are pre-allocated to ensure maintenance teams have everything needed for scheduled interventions.

- Predictive Analytics: With the rise of predictive maintenance, modern ERP systems leverage data analytics, IoT sensors, and machine learning algorithms to anticipate failures before they occur. By analyzing equipment telemetry, organizations can shift from time-based to condition-based maintenance, optimizing costs and reducing downtime.

Emergency Maintenance

Unlike routine maintenance, emergency maintenance is reactive and occurs unpredictably, requiring immediate attention. The primary challenges of emergency maintenance include:

- Asynchronous Demand: Emergency maintenance cannot be pre-scheduled, forcing organizations to maintain standby teams.

- Uncertainty in Resource Requirements: The root cause of failures is unknown until technicians arrive on-site. As a result, workforce teams must carry an assortment of spare parts, prioritizing commonly replaced components while avoiding excessive inventory costs.

- Inefficiencies in Travel and Deployment: Service teams may be deployed inefficiently, increasing travel time and delaying resolution. Advanced ERP solutions integrate geospatial analytics and dynamic dispatching algorithms to optimize technician assignments based on proximity and skill level.

Because emergency maintenance is critical to business continuity, companies invest heavily in minimizing response times. Industries such as healthcare impose strict regulations on emergency response times to prevent fatalities due to equipment failures (e.g., hospital elevators malfunctioning during critical patient transfers). Failing to provide rapid emergency maintenance can lead to legal liabilities, reputational damage, and financial losses.

Economic Implications of Maintenance Strategies

From an economic standpoint, maintenance operations generate revenue through service contracts and spare parts sales.

Definition

- Routine maintenance offers predictable revenue streams, allowing companies to plan inventory and workforce allocation efficiently.

- Emergency maintenance incurs unpredictable costs, often leading to higher operational expenses due to inefficient resource utilization.

For manufacturing companies, Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) are key performance indicators (KPIs) that influence maintenance planning. By integrating machine learning models with ERP systems, organizations can improve failure predictions, optimize spare parts inventory, and reduce emergency interventions.

There are multiple strategies for managing maintenance costs effectively. One option is outsourcing, but this comes with its own financial and strategic considerations. If a company decides to outsource maintenance, it must assess the costs and benefits carefully. In some cases, outsourcing might seem like a way to eliminate high internal maintenance costs, but this approach does not necessarily resolve all financial burdens. While routine maintenance can be outsourced profitably, emergency maintenance remains a challenge, as it is often unpredictable and resource-intensive.

Outsourcing Maintenance

Definition

Outsourcing maintenance services means partnering with third-party providers who take on the responsibility of maintaining equipment and infrastructure.

Third-party service providers typically prefer handling routine maintenance because it is predictable, profitable, and easier to manage. Emergency maintenance, on the other hand, is a high-risk and cost-intensive endeavor that few companies are willing to undertake alone.

When a business outsources maintenance, it often loses control over the most profitable part of its maintenance operations—routine servicing—while still being left with the burden of emergency repairs. Competitors may also enter the market, offering routine maintenance at competitive prices, further eroding the original company’s profitability. This is especially evident in industries where third-party providers can easily acquire the necessary technical expertise to perform maintenance, such as consumer electronics, HVAC systems, or vehicle servicing.

A significant challenge with outsourcing is that while it may reduce direct maintenance costs, it can have unintended consequences on brand reputation. If a third-party service provider fails to deliver prompt and effective emergency maintenance, the customer dissatisfaction ultimately reflects on the original company. Customers are likely to hold the brand accountable for poor service, even if the maintenance provider is at fault. This creates a paradox where outsourcing may appear to be a cost-saving measure but can result in long-term reputational and financial damage.

Maintenance as a Customer-Centric Service

Maintenance should not be viewed solely as a cost center but as a crucial service that enhances customer loyalty. When customers experience issues, they expect fast and efficient maintenance services. The timeliness and effectiveness of maintenance directly impact customer satisfaction and, consequently, brand loyalty.

A well-structured maintenance service can also create opportunities for businesses to introduce service contracts, such as prepaid maintenance plans. These plans allow customers to subscribe to routine maintenance services, reducing the likelihood of expensive emergency repairs. Such an approach is similar to an insurance model, where costs and risks are distributed among a large customer base. From a business perspective, this provides predictable revenue streams and improves financial planning for maintenance operations.

The Inefficiencies of Maintenance Without ERP

In the absence of an Enterprise Resource Planning (ERP) system, inefficiencies permeate every phase of the maintenance process. When a customer reports an issue, service center operators often fail to gather critical diagnostic information, resulting in an unstructured workflow. This lack of organization makes it difficult to allocate workforce resources effectively, leaving the company unaware of technicians’ availability. Appointments are scheduled vaguely, leading to delays and customer frustration.

When technicians arrive on-site, they are frequently uninformed about the problem at hand. Their initial visit typically addresses emergencies, but if resolving the root cause requires specialized expertise or additional spare parts, the issue remains unresolved. The delay extends as components are ordered, often taking weeks, and further appointments are scheduled. This cycle of inefficiency is compounded by the need for numerous administrative calls to coordinate follow-ups.

Operational inefficiencies are further exacerbated by challenges in inventory tracking. Without a structured system, maintenance personnel manage spare part stock in an ad hoc manner, leading to discrepancies. Smaller components often go unrecorded, while the use of larger parts may not be logged accurately. These tracking issues contribute to invoicing errors, as incomplete records hinder the generation of accurate invoices. Customers dispute charges due to unclear breakdowns, prolonging the resolution process and increasing administrative burdens. Altogether, the absence of an ERP system creates a cascade of inefficiencies that affect both customer satisfaction and operational effectiveness.

Optimizing Maintenance Through ERP Integration

In an optimized workflow, when a customer reports an issue, the service center engages in structured troubleshooting by asking relevant diagnostic questions. This allows the operator to gather crucial information about the failure, enabling predictive analysis to determine probable causes. With this data, the system can automatically identify the required spare parts and allocate a technician with the appropriate expertise.

A key advantage of ERP-driven maintenance is the intelligent scheduling of workforce resources. The system maintains a real-time overview of technician availability, ensuring that appointments are scheduled efficiently. Customers receive immediate confirmation of service visits, reducing uncertainty and frustration. Since technicians are pre-informed about the issue, they arrive prepared with the necessary tools and spare parts, significantly increasing the likelihood of resolving the problem in a single visit.

Furthermore, maintenance personnel are equipped with mobile devices that provide them with digital access to work orders, inventory databases, and customer history. This eliminates reliance on manual paperwork and ensures that all service-related data is logged in real time. Upon completing the maintenance task, the technician can generate an invoice on-site and provide the customer with an immediate digital receipt.

From an inventory management perspective, ERP integration ensures that spare parts usage is tracked with precision. The system records every component used during maintenance, updating stock levels accordingly, preventing stock shortages and enabling proactive restocking.

In addition to improving operational efficiency, an ERP-enhanced maintenance process enables proactive customer engagement. Following a successful repair, the technician can offer service subscriptions for routine maintenance.

By transitioning from a fragmented maintenance process to an ERP-integrated model, companies achieve several key benefits:

- Reduced Downtime: Faster issue resolution minimizes equipment unavailability.

- Optimized Resource Allocation: Technicians are dispatched efficiently based on skillset and availability.

- Enhanced Customer Satisfaction: Real-time updates and proactive communication improve service transparency.

- Accurate Invoicing: Automated tracking of spare parts and labor costs eliminates billing discrepancies.

- Increased Revenue Opportunities: Subscription-based maintenance services provide long-term value to customers.

Optimized Knowledge Management Process

Efficient knowledge management is critical for modern organizations, especially in customer service and technical support contexts. Key actions to optimize this process include the following:

-

Troubleshooting Workflow Systems: Use intelligent desktop applications to guide operators through diagnostic workflows tailored to specific product models and reported issues.

-

Workforce Coordination: Implement digital scheduling systems to optimize field service appointments based on technician expertise, location, and workload distribution. Advanced scheduling systems with predictive analytics enable dynamic resource allocation, ensuring service efficiency and minimal downtime.

-

Embedded Diagnostic Technologies:

- Devices with integrated sensors can detect and report malfunctions in real time, enabling proactive issue resolution.

- Proactive measures include self-service solutions or technician dispatch, improving overall service efficiency.

- Privacy concerns arise with telemetry data, especially in regions with strict regulations like GDPR.

-

Privacy and Data Governance:

- Organizations must obtain customer consent for data collection, offering tools for reviewing and modifying preferences.

- Strict data lifecycle management protocols are necessary to handle data deletion requests across distributed systems effectively.

-

Operational Logistics and Inventory Management:

- The Just-in-Time (JIT) inventory system minimizes costs by synchronizing spare parts delivery with demand.

- JIT requires robust supplier collaboration and seamless integration with diagnostic systems and logistics networks.

OTIS Elevators Case Study

The OTIS elevators case study provides a compelling example of how technological advancements and knowledge management can revolutionize an industry, transforming a traditionally cost-heavy maintenance process into a profitable and efficient service. Historically, elevator maintenance posed significant challenges, particularly in densely populated urban centers where reliable vertical mobility is critical. The conventional approach to maintenance was largely reactive—issues were addressed only after they had occurred, leading to frequent disruptions, high costs, and inefficiencies.

To tackle these inefficiencies, OTIS implemented a proactive maintenance strategy. The cornerstone of this transformation was the integration of smart sensors and predictive analytics. These technologies allowed OTIS to detect potential elevator malfunctions before they escalated into major failures, enabling the company to shift from emergency-based repairs to a structured routine maintenance process. By embedding intelligent monitoring systems in their elevators, OTIS ensured that maintenance teams could anticipate breakdowns and intervene preemptively, significantly reducing downtime and operational costs.

The impact of this transformation was profound. The deployment of these systems led to a 30% reduction in emergency maintenance interventions, a major milestone in optimizing workforce efficiency. Furthermore, recognizing the long operational lifespan of elevators, OTIS strategically retrofitted existing models with sensors where feasible and, in some cases, replaced older units with newer, sensor-equipped models at no cost to the building owners. This move not only streamlined maintenance processes but also solidified customer loyalty by demonstrating a commitment to long-term reliability.

A crucial aspect of this strategy was the introduction of a subscription-based maintenance model. Clients subscribing to this premium service benefited from real-time monitoring and 24/7 proactive maintenance interventions. OTIS established centralized control rooms where technicians continuously monitored elevator performance, ensuring rapid deployment of maintenance crews whenever irregularities were detected. This predictive maintenance framework effectively reduced service disruptions, enhancing overall user experience and operational efficiency.

From a business standpoint, the shift towards knowledge-driven maintenance not only transformed a cost-center into a revenue-generating segment but also reinforced OTIS’s competitive edge. By offering superior service quality, the company secured its position as the preferred choice among building managers, setting a benchmark for the entire elevator industry. This approach exemplifies how the integration of IoT-enabled monitoring, data analytics, and strategic business modeling can drive sustainable innovation in urban infrastructure management.

Utility Company Case Study

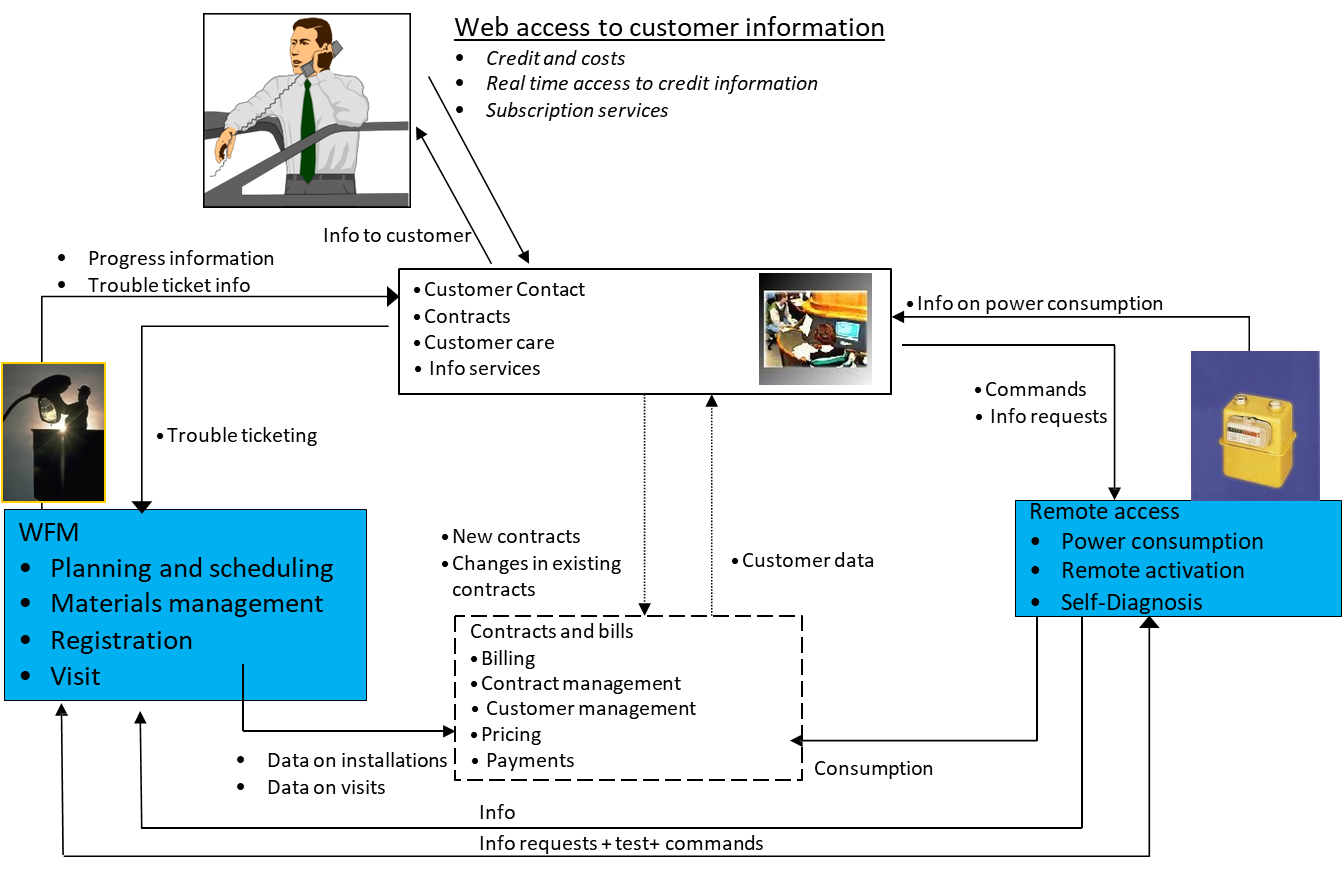

In parallel to OTIS’s transformation, utility companies have also leveraged technological innovations to enhance operational efficiency and improve customer experience. One of the most notable advancements in this domain has been the widespread adoption of intelligent metering systems. Unlike traditional electricity meters, which required manual readings and estimations, smart meters automatically transmit real-time consumption data to utility providers, ensuring accurate billing and improved demand forecasting.

Prior to the implementation of smart meters, electricity billing was often based on estimated usage, leading to overpayments and customer dissatisfaction. With smart meters, consumers now pay precisely for the energy they consume, eliminating inefficiencies associated with projected billing cycles. Additionally, these meters enable time-of-use pricing models, where electricity costs vary based on demand fluctuations throughout the day. For instance, customers are encouraged to operate energy-intensive appliances, such as washing machines, during off-peak hours, thus balancing the load on the power grid and promoting more efficient energy utilization.

Beyond billing improvements, smart meters have facilitated a data-driven approach to energy management. Utility companies can now analyze consumption patterns at an individual or grid-wide level, allowing for better resource allocation and reduced strain on infrastructure. Moreover, customers gain deeper insights into their energy consumption habits, fostering greater awareness and responsibility regarding their electricity usage.

The adoption of intelligent metering technology marks a shift towards a more decentralized and responsive energy distribution system, where real-time data not only enhances billing accuracy but also empowers both providers and consumers to make informed decisions regarding energy consumption.

Team Empowerment

The transformation witnessed in both the OTIS and utility company case studies underscores the importance of team empowerment in modern organizational frameworks.

Definition

Empowerment, in this context, refers to the strategic shift from highly specialized labor roles to more generalized, technology-enabled roles that allow employees to take on multiple responsibilities effectively.

Historically, workforce structures were built around rigid hierarchies, with employees assigned to highly specific tasks. However, the advent of information technology and automation has necessitated a transition towards a more dynamic and flexible workforce. Employees are now expected to be proficient in a broader range of functions, including customer service, data interpretation, and decision-making. This shift has been driven by the realization that technology alone cannot drive efficiency—human adaptability is equally crucial.

Organizations implementing workforce empowerment strategies focus on three key aspects:

- Training and Development: Equipping employees with technical skills, analytical capabilities, and customer engagement techniques to handle diverse responsibilities.

- Decision-Making Authority: Delegating operational decision-making to frontline employees, reducing response times and improving service quality.

- Incentive and Recognition Systems: Establishing performance-based reward structures to motivate employees to take initiative and align their efforts with organizational goals.

Example

For instance, in the case of OTIS, maintenance technicians are no longer just repair workers; they are also data analysts and customer relationship managers. Their role involves interpreting sensor data, anticipating issues, and ensuring client satisfaction. Similarly, in the utility sector, field technicians are trained to handle multiple aspects of service delivery, from meter installations to customer advisory roles.

This empowerment framework has been further reinforced by the introduction of enabling technologies such as smartphones, remote diagnostics tools, and AI-driven analytics platforms. These tools facilitate real-time collaboration, streamlined communication, and efficient problem resolution, ultimately enhancing workforce productivity and service reliability.