Predictive Maintenance (PdM) is an advanced maintenance strategy that aligns closely with the visionary concepts of Industry 4.0. Industry 4.0 itself represents a paradigm shift in manufacturing, envisioning the integration of novel technologies such as artificial intelligence, advanced robotics, and potentially even gene editing, thereby blurring the distinctions between physical, digital, and biological domains. While Industry 4.0 is a forward-looking concept, with many of its enabling technologies still under development or in nascent stages—much like the iterative advancements seen in web technologies (Web 2.0, 3.0, etc.)—it sets a clear direction for the evolution of manufacturing. This evolution compels companies to explore and exploit new technological capabilities to remain competitive.

Predictive maintenance, in this context, emerges as a critical component, aiming to optimize operational efficiency and reliability within these increasingly complex and interconnected manufacturing systems. The overarching goal, as often cited, is the attainment of maximum operational availability at minimum cost, a principle that necessitates a careful cost-benefit analysis for any adopted technology, including PdM.

The academic exploration of Industry 4.0, and by extension its constituent elements like PdM, often pushes far beyond current engineering capabilities, envisioning future states and potential impacts long before they materialize. This scientific approach, characterized by precision, cautious hypothesizing, and rigorous verification, leads to a slower but more robust understanding of complex systems. While immediate, revolutionary changes are not always feasible, the direction set by such visionary frameworks guides incremental advancements and prepares industries for future technological waves.

Fundamentals of Maintenance

Definition

Maintenance, in its broadest sense, encompasses all technical, administrative, and managerial actions undertaken throughout the lifecycle of an asset (defined as any technical component, device, subsystem, or system) to retain it in, or restore it to, a state where it can perform its required function.

The primary objective of maintenance is to delay the wear and tear on materials and prevent the decay of assets, thereby ensuring their sufficient availability to secure the high profitability of production systems.

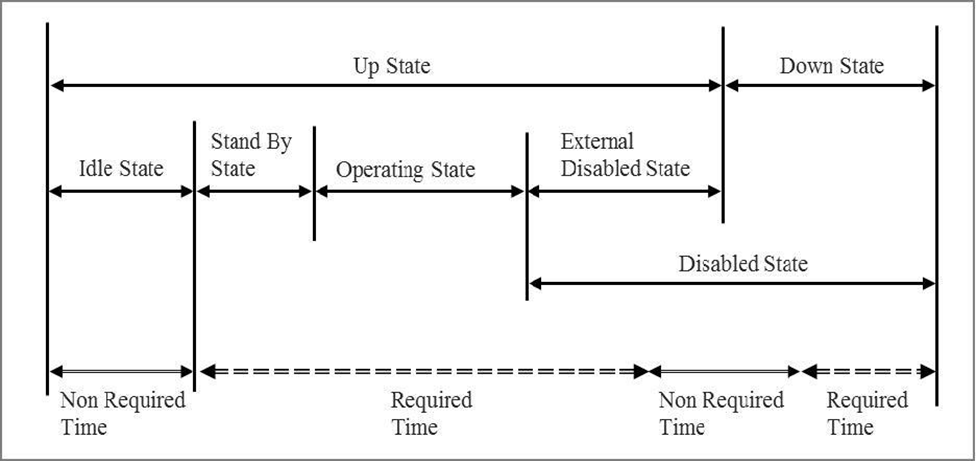

An asset can exist in various states, broadly categorized as ‘up’ (able to perform its function) or ‘down’ (unable to perform its function due to fault or ongoing maintenance). The ‘up’ state can be further subdivided into idle, standby, or operational states. Conversely, a ‘down’ state implies malfunction or unavailability due to planned interventions. Predictive maintenance, by its nature, involves planned interventions that might lead to a temporary ‘down’ or ‘disabled’ state for the asset.

Therefore, a critical understanding of these states and the associated costs and benefits of transitioning between them is essential. If maintenance can be scheduled during periods when the production infrastructure is not required, the associated costs of downtime can be significantly mitigated.

Maintenance activities are segmented into four main tasks:

graph LR Maintenance --> Repair Maintenance --> Inspection Maintenance --> Improvement Maintenance --> Service

- Inspection: Assessing the actual state of an item, identifying causes of attrition, and deriving necessary consequences for future operations (e.g., measuring brake disc thickness).

- Service: Actions aimed at sustaining the target state and delaying degradation (e.g., lubrication).

- Repair: Restoring an item to its functional state by replacing or fixing components, excluding improvements.

- Improvement: Technical and administrative measures to enhance functional reliability without altering the item’s required features (e.g., eliminating a failure point through design modification).

The ultimate aim is to achieve “maintenance time zero,” where all necessary services are conducted during idle states, ensuring no productive time is wasted.

The Strategic and Economic Impact of Maintenance

Historically, maintenance was often viewed merely as an operational expense. However, this perception has evolved, recognizing maintenance as a crucial cross-company business process that actively contributes to the value chain. While not directly adding value in the traditional sense, effective maintenance offers significant value-adding potential by facilitating highly efficient and smooth production or service delivery. Its contributions include the preservation of asset value, reduction of overall operational expenditure through optimized strategies, enhancement of temporal and functional utilization rates (which can free up capital for new investments), and the prevention of costly breakdowns that could impact plant safety, the environment, and process integrity. Studies have indicated that annual maintenance costs can represent a substantial portion of a nation’s GDP, and the consequential costs of deficient maintenance can be three to five times higher, highlighting the immense productivity value generated by effective maintenance. Efficient maintenance can influence up to

Several factors in modern industrial environments intensify the need for sophisticated maintenance management. The increasing flexibility and complexity of machinery, such as machining centers capable of diverse processing steps, come with high acquisition costs, pressuring organizations to maximize output capacity. Furthermore, mounting technological complexity, extended workloads, and accelerated machine processes can lead to a faster loss of effective reliability. The interdependency within current production systems means that the failure of a single machine can halt an entire manufacturing line, resulting in significant financial losses. Lastly, escalating requirements regarding environmental protection and operational safety, driven by legislation, necessitate robust maintenance and retrofitting of assets to meet enhanced liabilities.

Evolution of Maintenance Strategies

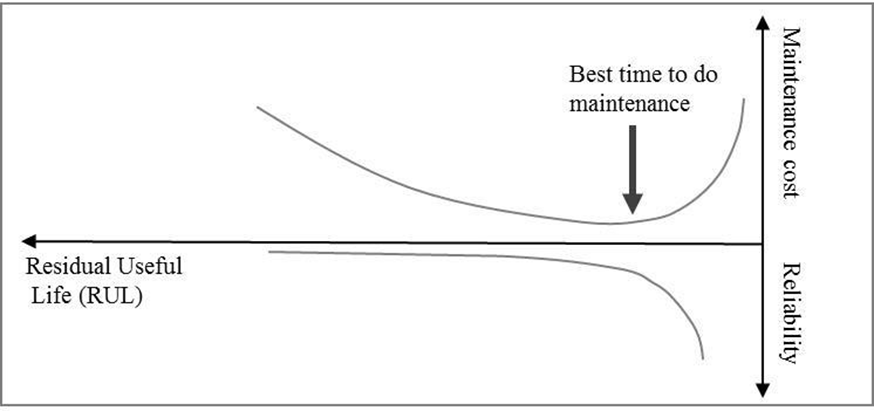

Maintenance strategies dictate how and when maintenance activities are performed to achieve specific objectives. A poorly chosen strategy can lead to excessive failures and impaired reliability, while an overly frequent strategy, though potentially improving reliability, can sharply increase costs by not fully utilizing an item’s residual useful life (RUL). An optimal strategy balances the exploitation of RUL with the assurance of reliability, considering economic, legal, safety, and technical requirements.

Maintenance strategies can be broadly categorized:

- Corrective Maintenance (Run-to-Failure): Maintenance is performed only after a fault or breakdown occurs. This approach maximizes the service life of an item in the short term and involves no planning costs. However, it can lead to enormous consequential costs due to unplanned downtime, safety hazards, and potentially more extensive damage.

- Preventive Maintenance: Maintenance is carried out at predetermined intervals or according to prescribed criteria, intended to reduce the probability of failure or the degradation of an item. This category can be further subdivided:

- Predetermined Maintenance (Time-Based): Maintenance actions are scheduled based on fixed time intervals (e.g., every 1000 operating hours) or usage counts, irrespective of the actual condition of the asset. This requires in-depth knowledge of item lifespans and allows for precise planning of staff and spare parts. It minimizes downtime from wear-out failures and offers high plannability, but it can lead to wasted RUL if components are replaced prematurely or fail to prevent random failures.

- Condition-Based Maintenance (CBM): Maintenance is performed based on the actual condition of an asset, determined through monitoring of specific parameters (e.g., vibration, temperature, oil analysis). This requires monitoring devices/systems, an IT infrastructure, and skilled staff. CBM aims to maximize both the productive time and the service life of items by performing maintenance only when necessary.

graph TD MS[Maintenance<br>Strategies] CM[Corrective<br>Maintenance] PM[Preventive<br>Maintenance] CBM[Condition-Based<br>Maintenance] PDM[Predictive<br>Maintenance] Pred[Predetermined<br>Maintenance] MS --> CM MS --> PM PM --> Pred PM --> CBM --> PDM

| Strategy | Trigger | Requirements | Pros | Cons |

|---|---|---|---|---|

| Corrective | Failure occurs | Skilled staff, spares, quick reaction | Max initial life, no planning cost | High failure costs, unplanned downtime, safety risks |

| Predetermined | Fixed intervals (time/usage) | Lifespan knowledge, planning | Reduces wear failures, high plannability | Wasted RUL, planning cost, doesn’t prevent random failures, labor-intensive |

| Condition-Based (CBM) | Condition threshold reached | Monitoring systems, IT infra., skilled staff | Maximizes productivity & life vs. predetermined | High investment (monitoring), requires analysis |

| Predictive (PdM) | Forecasted RUL / failure probability | CBM needs + data, models, algorithms, data science | Max productivity & life, high plannability, optimized timing | Very high investment (monitoring, IT, expertise), tech maturity/accuracy limitations |

Predictive Maintenance (PdM)

Predictive Maintenance (PdM) represents an advanced evolution of Condition-Based Maintenance. It extends automated condition monitoring with computerized evaluation of input data and intelligent prognostic capabilities.

Idea

The core idea is to predict impending failures by detecting early signs of degradation and estimating the remaining useful life (RUL) of components or systems.

While CBM describes the current health state, PdM forecasts prospective condition changes.

Definition

Predictive maintenance is defined as a maintenance policy which undertakes maintenance before product failures happen, by assessing the condition of the product, including operating environments and predicting the risk of product failure in real-time, based on the product data gathered.

The fundamental assumption underpinning PdM is that most failures do not occur instantaneously but rather evolve progressively from a normal to an abnormal state. By continuously monitoring relevant variables (workload, performance metrics, sensor readings) and comparing them against historical data of normal and abnormal operating behavior, PdM algorithms can identify deviations that signify degradation. Even if direct evidence of degradation is not apparent, PdM tools can exploit variables in operational processes and logistics data to discern the “footprint” of this degradation.

This requires a robust data infrastructure, including sensors integrated into equipment to capture real-time operational data, data transmission systems, and platforms for data storage and analysis. The ability to collect, process, and analyze large volumes of data is crucial for developing accurate predictive models.

| Advantages | Challenges & Limitations |

|---|---|

| Optimized Maintenance Scheduling: Enables service and repair at the optimal time, maximizing asset usefulness and RUL. | High Upfront Investment: Requires significant spending on sensors, data systems, IT infrastructure, and analytics software. |

| Reduced Unplanned Downtime: Anticipates failures, reducing costly unexpected breakdowns (potential downtime reduction up to 70%). | Need for Specialized Skills: Demands expertise in data science, machine learning, and equipment-specific knowledge. |

| Lower Maintenance Costs: Avoids unnecessary preventive actions and catastrophic failures (cost reductions up to 30-40%). | Data Requirements and Quality: Relies on large volumes of high-quality data, which may be difficult to obtain, especially for older equipment. |

| Enhanced Safety & Environmental Protection: Prevents failures that could pose safety or environmental risks. | Model Development and Validation: Building and maintaining accurate models is complex, requiring ongoing validation and updates. |

| Improved Resource Allocation: Allows more efficient planning of staff, spare parts, and tools. | Technological Immaturity: Some PdM technologies are still evolving, with limitations in diagnostic/prognostic accuracy for certain assets. |

| Diagnostic Insights: Provides analytical insights, prioritizes issues, and suggests corrective actions, reducing human error and reliance on experience. | Integration Complexity: Integrating PdM with existing ERP and CMMS systems can be challenging. |

| Limited Scope: Most effective for assets and failure modes with well-understood, measurable degradation patterns; not universally applicable or cost-effective for all equipment. |

The Implementation Journey

The decision to implement predictive maintenance hinges on a thorough cost-benefit analysis. While the potential savings in reduced downtime and maintenance expenditure are attractive, companies must weigh these against the significant initial investments in technology and expertise. Typically, organizations start with pilot projects focused on critical assets or known problem areas to demonstrate the value of PdM before a full-scale rollout. This allows them to gain experience, refine their models, and build a business case for broader adoption.

Predictive maintenance, at its core, leverages data science and advanced algorithms to enhance the traditional engineering goal of operational efficiency. Unlike innovations that require a complete overhaul of business models or the creation of entirely new services (which can be highly unpredictable and risky for established corporations), PdM often aligns with the existing “efficiency-focused” mentality prevalent in many manufacturing environments. This can make its adoption conceptually easier, as it aims to improve existing processes rather than invent new ones.

However, the journey involves more than just implementing algorithms. It may necessitate investments in new machinery equipped with appropriate sensors or retrofitting existing equipment. Furthermore, establishing the data science capabilities, software development, and operational processes to run these systems continuously and automatically is a considerable undertaking, often requiring new organizational skills and structures.

The adoption of PdM is often incremental. Companies might start by predicting specific types of events for which they have reliable data and a clear understanding of degradation patterns. As they gain more data, experience, and confidence, they can expand the scope of their PdM program to cover more assets and failure modes. The key is to demonstrate tangible benefits early on to justify continued investment and foster organizational buy-in.