Porter’s Concept of Information Intensity

Michael Porter, a renowned scholar in business strategy, introduced the concept of information intensity as part of his broader analysis of how organizations leverage information technology to enhance their operational efficiency. His approach involves simplifying a complex problem—namely, how companies can effectively integrate information technology (IT) into their diverse processes—by defining key concepts that provide a structured framework for analysis.

Porter’s perspective differs from traditional organizational theories, which often struggle to address the specific nature of tasks within companies. Instead, he adopts a more practical, management information systems (MIS) perspective, focusing on how IT can be applied to real-world business operations. Through this lens, he identifies three fundamental aspects that influence the degree to which IT contributes to a company’s functionality: information intensity, IT intensity, and management information. These concepts help managers assess how extensively their organization relies on information to operate effectively.

Information Intensity

Definition

Information intensity refers to the amount and complexity of information required to support an organization’s processes.

This concept is crucial in distinguishing industries that rely heavily on information processing from those that do not. Essentially, it measures how embedded information is within both the product or service offered by the company and the operational processes behind it.

From a technical standpoint, the concept of information intensity can be analyzed through the structure and flow of data within an organization. High information-intensive industries typically rely on database management systems, real-time processing, and automated decision-making algorithms to handle vast amounts of structured and unstructured data. Cloud computing, big data analytics, and AI-driven insights further enhance an organization’s ability to manage complex information flows efficiently.

Example

For example, in high-frequency trading (HFT) within the financial sector, algorithmic systems analyze market data and execute transactions in milliseconds, demonstrating a peak level of information intensity. Similarly, in healthcare information systems, patient records, diagnostics, and treatment plans are managed through interconnected digital platforms, ensuring the continuous exchange of critical medical data.

By contrast, industries with low information intensity may have simpler IT infrastructures, with information systems primarily used for administrative tasks such as inventory management, basic reporting, and workflow automation. These industries do not require extensive computational power or real-time data processing to sustain their operations.

IT Intensity

Michael Porter’s concept of IT intensity builds upon the idea of information intensity by examining how industries not only rely on information, but also differ in the extent to which information technology (IT) supports their processes. While two industries may share a high level of information intensity, their IT intensity can vary significantly due to differences in how information is processed, the nature of their operational tasks, and the technological advancements available at a given time.

Porter emphasizes that IT intensity is influenced by both the characteristics of the industry and the state of technological development. In some cases, an industry may require extensive information processing, but the existing IT solutions may not be advanced enough to fully automate or optimize those processes. This dynamic nature of IT intensity means that it evolves continuously as new technologies emerge, making certain industries increasingly reliant on IT over time.

Comparative Analysis: Banking vs. Insurance

A key example Porter provides to illustrate differences in IT intensity is the comparison between the banking and insurance industries. Both sectors exhibit high information intensity, as they depend on managing vast amounts of customer data, financial transactions, and risk assessments. However, the degree to which IT can automate and streamline operations differs considerably between the two industries.

In the banking sector, most financial transactions can be fully automated. Money transfers, online payments, and credit card transactions occur electronically with minimal human intervention. Modern banking relies on real-time processing systems, digital payment networks, and automated decision-making algorithms that execute transactions almost instantaneously. Although some back-office operations still require human oversight, particularly for security and fraud prevention, the size of these manual operations has decreased significantly over time. The high degree of automation in banking illustrates an industry with both high information intensity and high IT intensity, as IT solutions can effectively support and enhance its core processes.

In contrast, the insurance industry, despite also being information-intensive, requires a higher degree of human judgment and manual intervention in its decision-making processes. Consider the case of insuring a restaurant: unlike banking transactions, determining the appropriate insurance policy involves multiple complex variables that cannot be fully assessed by algorithms alone. Factors such as building safety compliance, fire hazards, and operational risks require in-person evaluations and expert assessments. While IT systems can assist in standardizing forms, analyzing risk factors, and managing client databases, they cannot entirely replace the role of human expertise. This limitation results in a lower IT intensity compared to banking, as a substantial portion of the industry still depends on manual evaluations and tailored decision-making.

The concept of IT intensity is not static; it changes over time as technology evolves. Innovations in artificial intelligence, machine learning, and big data analytics are increasing IT intensity in industries that were previously less dependent on automation. For example, in the insurance sector, advancements in computer vision and IoT (Internet of Things) devices allow for more automated risk assessments. AI-powered algorithms can now analyze satellite images to assess property damage or detect fraud, reducing the reliance on manual inspections.

However, some industries will always retain a degree of human intervention. Consider the case of high-end tailoring, where custom clothing is crafted to fit an individual’s unique body shape and preferences. Unlike mass-produced fashion, which benefits from IT-driven standardization, luxury tailoring relies on the skill of expert craftsmen. Here, the need for personalized, manual labor results in low IT intensity, as automation would compromise the very essence of the product’s value.

Industrialization, Standardization, and IT Integration

The adoption of IT in operational processes is closely tied to standardization. Industries that produce highly standardized products and services are more likely to benefit from IT-driven automation, whereas those that require customization, craftsmanship, or human judgment will have a lower IT intensity. Manufacturing industries, for example, have progressively increased their IT intensity through robotics, AI-driven quality control, and predictive maintenance. In contrast, fields such as luxury goods, specialized consulting, and creative industries retain lower IT intensity due to the irreplaceable value of human expertise.

From a technical perspective, IT intensity can be evaluated based on several factors, including:

- Degree of automation: The extent to which processes can be executed without human intervention.

- Dependence on real-time data processing: The necessity of IT systems to handle large volumes of information dynamically.

- Adaptability to new IT solutions: The industry’s ability to integrate emerging technologies such as AI, cloud computing, and blockchain.

Key Drivers of IT Intensity

Several factors determine the IT intensity within a business context:

-

Process Structuring – Highly structured business processes are easier to translate into software applications. For example, operational workflows in manufacturing are often well-defined, making them more amenable to automation compared to unstructured decision-making tasks in service industries.

-

Data Volume – Companies handling large volumes of data derive greater benefits from IT adoption. Automating data processing reduces errors, improves efficiency, and enables real-time insights that would be impractical to achieve manually.

-

Process Frequency – Repetitive processes justify automation investments. If an organization performs a specific analytical task frequently, coding a software solution in Python may be more efficient than relying on manual Excel computations.

-

Operational Complexity – Contrary to intuition, simpler tasks are often automated first because they provide quicker and more reliable returns. Complex processes require extensive debugging and refinement, making them more challenging to implement effectively in an IT system.

In real-world business settings, automation decisions balance efficiency, cost, and technical feasibility. While it may be tempting to pursue ambitious IT projects, successful implementation often starts with incremental improvements. For startups and enterprises alike, an effective strategy involves prioritizing low-hanging fruit—automating straightforward processes before tackling more complex challenges.

Management Inclination and IT Strategy

Definition

Management inclination refers to the extent to which an organization’s leadership views information technology (IT) as a strategic asset.

This perspective significantly influences how companies integrate IT into their operations and decision-making processes. Some companies see IT as a crucial enabler of efficiency and innovation, while others may treat it merely as a supporting function, leading to vastly different outcomes in business performance and competitiveness.

For instance, consider a scenario where a company expands into a new market segment that requires standardized production and enhanced IT support. Without prior experience or a strategic IT vision, the company might struggle to adapt. The difference in mindset between operational execution and strategic management becomes evident in such cases. The company may excel at execution but falter in navigating the complexities of IT-driven business transformation. As a result, some business initiatives fail not because of market demand but due to a lack of managerial foresight in leveraging IT effectively.

IT adoption within an organization is also shaped by corporate culture and managerial expertise. Traditional managers, who are accustomed to established technologies, often face challenges in adapting to emerging trends like big data analytics and machine learning. Unlike mechanical technologies, which have well-defined functions and predictable outputs, IT systems evolve rapidly, offering diverse and industry-specific applications. This continuous evolution necessitates a mindset that embraces experimentation and iterative learning.

A fundamental issue with IT adoption is that managers typically understand what technology does but not how it works. Unlike mechanical systems, where functionalities remain static, IT systems are dynamic and subject to frequent innovation. Artificial intelligence, for example, can be applied in numerous ways, with its impact varying across industries. Some managers may perceive AI as a tool to replace human decision-making, while others see it as an augmentation mechanism. The challenge lies in striking a balance between leveraging automation and retaining human expertise in critical decision-making areas.

IT Intensity vs. IT Adoption

IT intensity refers to the theoretical potential of information technology to enhance business processes within an industry, whereas IT adoption measures the actual level of implementation.

An industry may have high IT intensity, meaning IT has the potential to significantly improve operations, yet adoption may remain low due to managerial reluctance. This reluctance often stems from risk aversion, budget constraints, or a lack of technical expertise among decision-makers.

The Relationship Between IT Intensity and Industry Dynamics

Information intensity, the extent to which information processing is integral to an industry, is generally higher in service-oriented sectors compared to manufacturing. In services, information itself constitutes a part of the product, influencing customer interactions and decision-making. However, IT intensity can sometimes be higher in manufacturing, particularly when automation technologies reach a level where they provide a competitive advantage. Historically, IT solutions for manufacturing, such as Enterprise Resource Planning (ERP) systems and Computer-Aided Manufacturing (CAM), became widely available earlier than comparable service-sector solutions. This earlier availability contributed to a stronger IT orientation in manufacturing management.

Despite this, modern economies are increasingly service-driven, with services constituting over 70% of GDP in many countries. This shift presents significant opportunities for IT-driven innovation in service industries, particularly in areas like artificial intelligence, cloud computing, and automated decision support systems. The delayed IT adoption in services suggests that there remains substantial untapped potential for digital transformation.

Manufacturing Production Processes

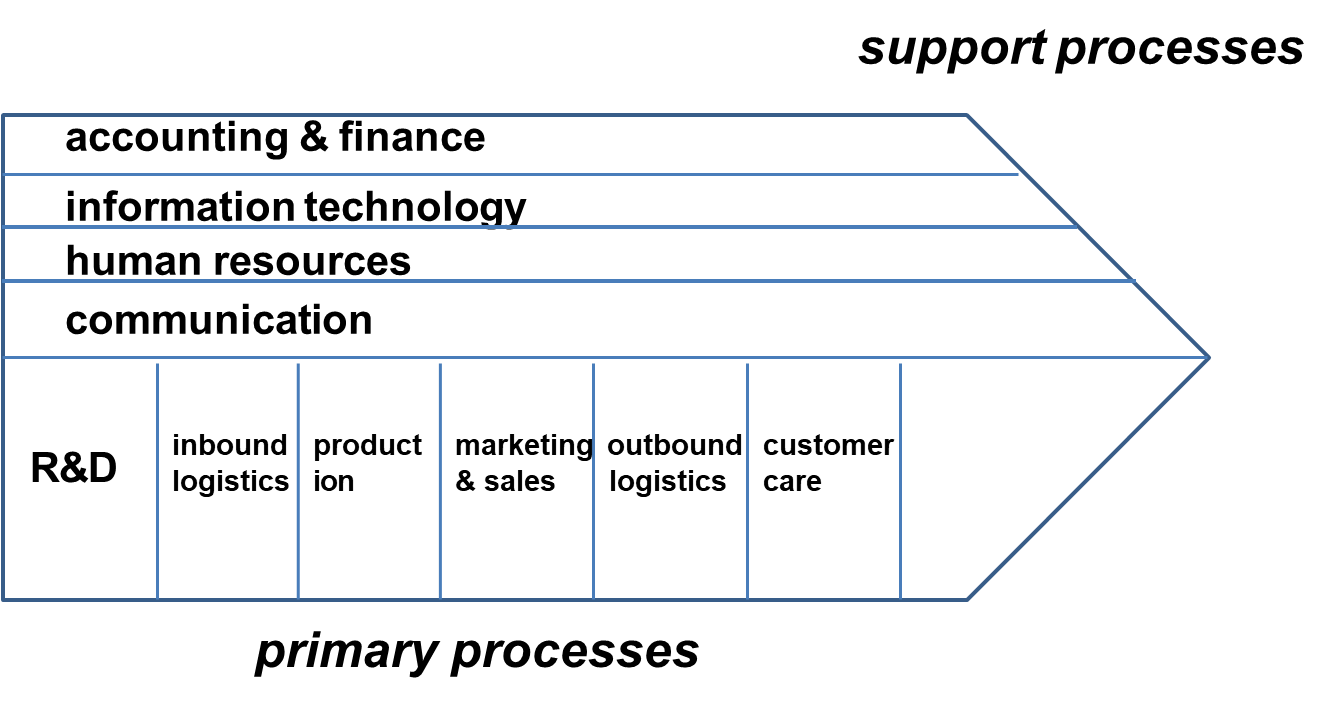

Manufacturing production processes and their integration with inter-functional information systems represent a critical area of study for understanding how modern organizations optimize operations. To analyze this, Michael Porter’s value chain model serves as a foundational framework. Unlike hierarchical organizational structures, which emphasize vertical coordination, Porter’s model adopts a process-oriented view. This perspective prioritizes the flow of activities across functional boundaries, emphasizing how tasks such as research and development (R&D), procurement, production, marketing, and customer support interconnect to deliver products to market.

The value chain framework categorizes these activities into primary processes (directly tied to product creation and delivery) and support processes (horizontal functions like IT, human resources, and finance that enable primary processes). By focusing on processes rather than hierarchies, the model highlights how information technology (IT) can streamline workflows, reduce bottlenecks, and enhance decision-making across departments.

Primary Processes and IT Integration

The manufacturing value chain begins with R&D, where product design and innovation occur. IT tools such as CAD software and simulation platforms enable engineers to prototype digitally, test materials, and optimize designs before physical production. Following R&D, inbound logistics involves procuring raw materials and managing supplier relationships. Here, enterprise resource planning (ERP) systems automate inventory tracking, supplier communication, and order fulfillment, ensuring materials arrive just-in-time to minimize storage costs.

Production itself relies heavily on IT for automation and precision. PLCs, robotics, and manufacturing execution systems monitor assembly lines, adjust workflows in real time, and collect data on machine performance. After production, outbound logistics manages distribution networks, leveraging GPS tracking and warehouse management systems to optimize delivery routes and inventory placement.

Marketing and sales utilize customer relationship management platforms to analyze purchasing patterns, tailor promotions, and forecast demand. Finally, customer service employs IT tools like chatbots and service portals to resolve issues efficiently, ensuring post-sale satisfaction.

Support Processes and Cross-Functional Coordination

Support processes underpin the entire value chain by providing shared resources. For instance, IT infrastructure enables seamless data exchange between R&D, production, and logistics teams. Similarly, human resource management systems (HRMS) standardize recruitment, training, and performance evaluations across departments. Accounting and finance software automates invoicing, tax compliance, and financial reporting, ensuring regulatory adherence while freeing resources for strategic tasks.

A critical yet often overlooked support process is corporate communication, which ensures consistent messaging internally (e.g., aligning teams on production goals) and externally (e.g., branding and sustainability reporting). Modern communication tools like intranets and social media management platforms help organizations articulate their mission beyond profit—such as environmental commitments or social initiatives—to build stakeholder trust.

The integration of IT into manufacturing introduces technical challenges. For example, interoperability between legacy systems (e.g., on-premises ERP) and modern cloud-based platforms requires middleware solutions to bridge data silos. Cybersecurity also becomes paramount, as interconnected systems increase vulnerability to breaches. Additionally, advanced analytics and machine learning algorithms process vast datasets from production lines to identify inefficiencies, predict maintenance needs, and optimize resource allocation.

Porter’s value chain model underscores a paradigm shift: companies can no longer rely solely on hierarchical decision-making. Instead, they must adopt horizontal coordination mechanisms. For example, real-time data sharing between procurement and production teams ensures material availability aligns with manufacturing schedules. Similarly, feedback loops between customer service and R&D enable iterative product improvements. IT acts as the enabler of this coordination, providing tools like collaborative platforms (e.g., Slack, Microsoft Teams) and integrated databases that break down functional barriers.

The evolution of IT in manufacturing has transformed traditional workflows. For instance, digital twins—virtual replicas of physical systems—allow engineers to simulate production scenarios and test changes without disrupting operations. Blockchain technology enhances supply chain transparency by recording transactions in immutable ledgers, reducing fraud risks. Meanwhile, AI-driven quality control systems inspect products at microscopic levels, ensuring compliance with stringent standards.

Development and Logistics Cycles

Manufacturing production processes are characterized by cyclical, interlinked activities that ensure the continuous creation, refinement, and delivery of products. These cycles—primarily the development cycle and logistics cycle—form the backbone of industrial operations. Their repetitive nature enables companies to adapt to market demands, optimize resource use, and maintain competitive agility.

Development Cycle: From Prototyping to Industrialization

The development cycle governs the design, refinement, and industrialization of new products. It begins with conceptualization, where ideas are transformed into tangible prototypes using tools like CAD software and 3D printing. Prototypes serve as functional models to validate feasibility, gather stakeholder feedback, and identify design flaws.

Once a prototype is validated, the focus shifts to industrialization—the process of scaling the design for mass production. This phase involves material selection, cost analysis, and process engineering. Engineers must address challenges such as:

- Material compatibility: Ensuring raw materials meet durability, cost, and regulatory standards.

- Production line configuration: Designing workflows to minimize bottlenecks (e.g., using lean manufacturing principles).

- Quality assurance: Implementing statistical process control to maintain consistency.

A critical output of this phase is the minimum viable product, which balances functionality and market readiness. Achieving an MVP requires iterative testing, often supported by agile methodologies.

Logistics Cycle

The logistics cycle ensures the seamless flow of materials, transformation processes, and product delivery. It comprises three interdependent stages:

-

Procurement and Inbound Logistics Procurement involves sourcing raw materials, negotiating supplier contracts, and managing inventory. Modern systems like enterprise resource planning (ERP) integrate real-time data from suppliers, enabling just-in-time (JIT) inventory practices. RFID tags and IoT sensors track shipments, reducing delays and stockouts.

-

Production and Process Automation Production transforms materials into finished goods through automated and manual processes. Advanced manufacturing technologies include:

- Programmable logic controllers (PLCs): Automate assembly lines by regulating machinery speed and precision.

- Robotic process automation (RPA): Deploy collaborative robots (cobots) for tasks like welding or packaging.

- Manufacturing execution systems (MES): Monitor production metrics (e.g., cycle time, defect rates) to optimize efficiency.

-

Sales, Distribution, and Post-Sale Services Post-production, the focus shifts to fulfilling orders and managing customer relationships. Outbound logistics relies on warehouse management systems (WMS) and route optimization algorithms to streamline delivery. Customer relationship management (CRM) platforms analyze purchasing patterns to forecast demand and tailor marketing campaigns. Post-sale services, such as maintenance contracts or IoT-enabled predictive maintenance (e.g., smart appliances alerting users to component failures), enhance long-term customer loyalty.

Technical Challenges in Cycle Integration

Integrating development and logistics cycles demands robust IT infrastructure and interoperability. Key challenges include:

- Data silos: Legacy systems in procurement may lack compatibility with modern MES platforms, requiring middleware solutions.

- Cybersecurity: Interconnected IoT devices in smart factories are vulnerable to cyberattacks, necessitating encrypted networks and zero-trust architectures.

- Scalability: Cloud-based ERP systems must handle fluctuating demand without latency, particularly in global supply chains.

For example, a food processing company might struggle to synchronize real-time inventory data across continents due to inconsistent network bandwidth, leading to overstocking or shortages.

Information systems act as the glue between development and logistics cycles. Key technologies include:

- Digital twins: Virtual replicas of production lines allow engineers to simulate changes (e.g., introducing a new machine) without disrupting operations.

- Predictive analytics: Machine learning models analyze historical data to predict material shortages or equipment failures.

- Collaborative platforms: Tools like Microsoft Teams or Slack enable cross-functional teams (R&D, procurement, sales) to share updates in real time.

A case in point is the aerospace industry, where digital twins of jet engines are used to test performance under extreme conditions, reducing physical prototyping costs by 40%.

Interfunctional Information Processes

In modern organizations, the concept of value chains has shifted focus from isolated functions to integrated systems and processes. This shift emphasizes the importance of end-to-end processes that span multiple hierarchical functions within a company. These processes encompass a wide range of activities, from the procurement of raw materials to the delivery of post-sales services. Each instance of an end-to-end process involves multiple cycles of activities that require seamless coordination across various departments. This interconnectedness is not surprising, as organizations are inherently designed to foster cooperation through specialization. In other words, multiple functions must collaborate to achieve a common goal, which is the essence of interfunctional processes.

The primary objective of streamlining these cross-functional processes is to enhance organizational flexibility and information processing capacity. Companies that can efficiently manage exceptions and adapt to changing circumstances are better positioned to meet customer demands and maintain a competitive edge. A critical aspect of this flexibility lies in the management of interfunctional information processes: these processes are intrinsically linked to the physical production process, as they carry and manage the information necessary to coordinate production activities.

Interfunctional information processes are essential because they enable organizations to coordinate production activities, handle exceptions, and rapidly adjust plans.

Example

If a company lacks the necessary information to coordinate its processes, it cannot make informed decisions or adapt to unforeseen challenges. This lack of flexibility can lead to inefficiencies, customer dissatisfaction, and ultimately, a loss of competitive advantage. Therefore, the ability to manage and process information across functions is a cornerstone of modern organizational success.

The complexity of interfunctional information processes becomes evident when examining operational databases, which store the data required to manage these processes. In practice, operational databases may contain hundreds of tables, each corresponding to different aspects of the business. Ideally, an operational database should maintain a comprehensive history of each order, including details such as customer information, delivery schedules, and maintenance interventions. However, the reality is often more complex, as data may be distributed across numerous tables, each with its own structure and level of consistency.

To simplify this complexity, interfunctional information processes can be categorized into three main types, each corresponding to specific tables in the operational database.

- The first is the order management process, which tracks the lifecycle of an order from inception to post-sales services. This process is typically associated with a table in the operational database that uses an order ID as its primary key. The order ID serves as a unique identifier that links all related information, such as customer details, delivery schedules, and invoices.

Example

For example, when a supplier submits an invoice, it must reference the corresponding order ID to ensure that the invoice is correctly associated with the order. This linkage is crucial for coordinating activities such as payment processing and inventory management.

-

The second type of interfunctional information process is the inventory management process, which oversees the flow of goods and materials throughout the supply chain. This process involves tracking inventory levels, managing stock replenishment, and ensuring that products are available to meet customer demand. The corresponding tables in the operational database might include information on product attributes, stock levels, and supplier details. However, inconsistencies can arise, particularly when dealing with products from recently acquired companies that may not yet be fully integrated into the organization’s information system.

-

The third type is the production planning process, which focuses on coordinating production activities to meet demand while minimizing costs and maximizing efficiency. This process involves creating and adjusting production schedules, allocating resources, and monitoring progress. The associated tables in the operational database might include data on production schedules, resource availability, and quality control metrics. As with the other processes, the challenge lies in ensuring that the data is consistent, up-to-date, and easily accessible for decision-making.

Order Management Process

The Order Management Process is a critical component of organizational operations, particularly in industries where production is tailored to customer demand. This process begins when a customer places an order and continues through to the delivery of the product and post-sales services. However, the order management process does not operate in isolation; it is deeply interconnected with materials management and operations management, forming a cohesive system that ensures efficiency, traceability, and customer satisfaction.

Materials Management

Definition

Materials management is a logistical process that ensures the availability of raw materials and components required for production.

In many cases, materials are ordered from suppliers before a customer order is received, especially in industries where production is not strictly on-demand. For example, a company manufacturing consumer goods might maintain a stock of raw materials to ensure smooth production cycles. However, in industries like custom heating and air conditioning systems, production is often project-based and initiated only after a customer order is confirmed. In such cases, the supplier’s Enterprise Resource Planning (ERP) system generates an order number, and materials are procured specifically for that project. This approach, known as on-demand production, requires precise coordination to avoid delays and ensure that materials are available when needed.

Once materials are ordered, they are assigned a unique identifier (ID) that tracks them throughout their lifecycle. This ID is crucial for traceability, as it allows the company to monitor the materials from the moment they are received in the warehouse, through their consumption in production, and even during post-sales activities. This traceability is essential for assessing supplier performance, managing warranties, and ensuring accountability. If a material is found to be defective and is still under warranty, the supplier may be responsible for covering the cost of replacement, thereby protecting the manufacturer from financial losses.

Operations Management

Operations management focuses on the execution of production activities, ensuring that materials are transformed into finished products efficiently and on schedule. This process involves planning, scheduling, and monitoring production activities, as well as coordinating logistics to deliver the final product to the customer. Operations management is closely tied to both order and materials management, as it relies on accurate information about customer orders and material availability to function effectively.

Consider a scenario where a high-priority customer calls to check the status of their order, emphasizing the urgency of timely delivery. In such cases, the company must be able to quickly assess the status of production activities and adjust its operations plan accordingly. This might involve reprioritizing the order, rescheduling production tasks, or reallocating resources to meet the customer’s deadline. Without real-time information on operations, the company would be unable to respond effectively, risking customer dissatisfaction and potential loss of business.

The Operations Management Process is a cornerstone of organizational efficiency, encompassing the planning, execution, and monitoring of production activities. This process is deeply intertwined with other functional areas, such as sales, materials management, and research and development (R&D), creating a complex web of information exchange that drives decision-making and operational success.

Definition

At its core, operations management ensures that production activities align with customer demands, resource availability, and organizational goals.

To achieve this, it relies on a steady flow of accurate and timely information, which is often produced by one function and consumed by another. This division of labor in information production and consumption is a fundamental aspect of modern organizational structures.

Operational Database

The operational database serves as the central repository for all information related to orders, materials, and operations. It stores data such as order IDs, material IDs, production schedules, and delivery timelines, enabling seamless coordination across functions. This integration ensures that every department has access to the information it needs to perform its tasks effectively.

However, managing an operational database is not without challenges. In real-world scenarios, these databases can contain hundreds of tables, each with its own structure and level of consistency. Data scientists and IT professionals must navigate this complexity to extract and analyze the information required for decision-making. For example, when preparing data for machine learning models, they must identify relevant columns from multiple tables, account for inconsistencies, and ensure that the data is clean and reliable.

Process Certification and Global Standards

In today’s globalized economy, organizations must adhere to stringent quality and process standards to remain competitive. Certifications such as ISO 9001 validate a company’s ability to manage its processes effectively, ensuring that it can consistently deliver high-quality products and services. These certifications focus not only on the final output but also on the efficiency and coordination of production processes.

Info

An ISO 9001 audit might evaluate whether a company has a well-organized system for handling orders, managing inventory, and coordinating production activities. By meeting these standards, organizations demonstrate their commitment to operational excellence and customer satisfaction.

Process certification also plays a crucial role in financial management. Accurate and well-organized operational data enables companies to make informed decisions about resource allocation, budgeting, and investment. For instance, the Chief Financial Officer (CFO) relies on operational data to project cash flow, assess financial health, and plan for future investments. If the CEO proposes a new investment, the CFO must determine whether the company has sufficient funds or if it needs to liquidate assets or delay the investment until profits are realized.

Integrating Operational and Executive Portfolios

The operational database serves as the foundation for both operational and executive decision-making. While operational teams use this database to manage day-to-day activities, executive teams rely on it for strategic planning and high-level coordination. For example, operational data on production schedules and material consumption can inform strategic decisions about expanding production capacity or entering new markets. Similarly, information about customer orders and market trends can guide R&D efforts, ensuring that the company develops products that align with customer preferences and market demands.

This integration of operational and executive portfolios highlights the importance of data accessibility and transparency. In theory, all users within an organization should have access to the information they need to perform their roles effectively. However, access must be carefully managed through user profiles and permissions to protect sensitive data and maintain security. At the same time, organizations must remain flexible, as unexpected situations may require individuals to access information outside their usual scope. This flexibility is essential for handling exceptions and adapting to changing circumstances, which are inevitable in dynamic business environments.

Standard vs. Custom Production

In the realm of production systems, the distinction between standard and custom production is fundamental and has significant implications for the design and operation of information systems. This distinction is deeply rooted in economic principles and is crucial for understanding how businesses manage their production processes, inventory, and customer satisfaction.

| Pros | Cons | |

|---|---|---|

| Custom Production | - High degree of customer satisfaction - Flexibility to meet unique requirements - Potential for premium pricing | - Longer lead times - Higher production costs - Complexity in managing resources |

| Standard Production | - Economies of scale - Efficient production processes - Lower production costs | - Limited customization options - Inventory management challenges - Potential for overproduction |

Custom Production

Definition

Custom production, also known as on-demand production, involves creating products that are specifically designed to meet the unique requirements of a customer. This approach is highly flexible but often requires a more complex and time-intensive process.

A classic example of custom production is the design and installation of a heating system for a building. Unlike off-the-shelf products, a heating system must be tailored to the specific characteristics of the building, such as its size, number of windows, insulation quality, and desired indoor temperature. This necessitates a detailed design process, where engineers gather precise information about the building and its requirements.

In many cases, this information is not readily available in existing information systems. For instance, details like the dimensions of windows or the maximum external temperature the system must handle may require on-site measurements and expert analysis. Once the design is finalized, an order is placed, and production begins. This is the essence of on-demand production: materials are purchased, and manufacturing starts only after a concrete customer order is received.

However, this approach comes with inherent delays. The time required to fulfill a customer order includes not only the production process but also the procurement of materials, which may involve placing orders with suppliers, waiting for deliveries, and managing logistics. These factors make custom production a more time-consuming and resource-intensive process compared to standard production.

Standard Production

Definition

Standard production focuses on creating products with a limited set of features that can be mass-produced and stored in inventory. This approach is characterized by predictability and efficiency, as production is not tied to individual customer orders.

A common example of standard production is the automotive industry. When you purchase a car, you can choose from a range of predefined options, such as color, trim, and additional features. However, you cannot request entirely custom modifications, such as a broader trunk or a uniquely designed interior.

In standard production, companies produce goods based on forecasts of future demand rather than specific orders. This allows them to maintain stock levels and fulfill orders quickly, as the products are already manufactured and ready for delivery. For instance, if a car dealership has a specific model in stock, a customer can drive it home within days, after completing administrative formalities like registration. However, if the customer requests a specific color or optional feature that is not in stock, the waiting time increases, as the manufacturer must complete additional production steps to meet the request.

The key advantage of standard production is its efficiency. Companies can achieve economies of scale by producing large quantities of standardized products, reducing per-unit costs and minimizing lead times. Additionally, standard production simplifies inventory management and allows for better planning and control of resources. However, this approach may limit customer satisfaction, as it offers less flexibility in terms of product customization.

Balancing Custom and Standard Production

In practice, most companies operate somewhere along the continuum between fully custom and fully standard production. The optimal balance depends on market demand, competitive strategy, and the nature of the product. For example, some customers may be willing to wait longer for a customized product that meets their exact specifications, while others prioritize immediate availability and are satisfied with standard options. Companies must carefully analyze their target market and adjust their production strategies accordingly.

Implications for Information Systems

The choice between standard and custom production has significant implications for the design and functionality of information systems, particularly Enterprise Resource Planning (ERP) systems. In custom production, information systems must support complex design processes, project management, and coordination with suppliers. They need to handle detailed customer specifications, track the progress of individual orders, and manage contingencies such as delays or changes in requirements.

In contrast, standard production relies on information systems that emphasize forecasting, inventory management, and efficient distribution. These systems must track stock levels, predict future demand, and ensure that products are available for immediate delivery. Additionally, they should support the integration of customizable options, allowing companies to offer a degree of personalization without disrupting the overall production process.

Modern ERP systems are designed to support both standard and custom production, as most companies operate in a hybrid environment. For example, a manufacturer might have some production lines dedicated to standard products, while others handle custom orders. The ERP system must seamlessly integrate these different processes, providing real-time visibility into inventory, production schedules, and customer orders. This requires advanced functionalities such as demand forecasting, supply chain management, and production planning, all of which are critical for optimizing operations and meeting customer expectations.