The distinction between manufacturing and service companies lies primarily in the nature of the tasks they perform and the types of products or services they offer.

Definition

Manufacturing companies are primarily engaged in the production of tangible goods. Tangibility implies that the products they create can be physically handled, stored, transported, and insured.

Examples include automobiles, electronics, furniture, and industrial equipment. Because these goods exist in a physical form, they can be subjected to quality control inspections, inventory management processes, and logistical considerations.

Definition

Service companies provide intangible offerings. Services are actions, expertise, or experiences that cannot be physically touched or stored in the same way as manufactured goods.

Examples include banking, consulting, healthcare, and education. While some services may produce documentation, such as an insurance policy or a printed contract, the core value of a service lies in the expertise, labor, or convenience provided rather than a physical product.

The way these two industries adopt and implement information technology (IT) differs significantly:

- Manufacturing companies have been early adopters of IT solutions due to the complexity of their production processes, supply chain management, and large-scale planning requirements. They have integrated technologies such as Enterprise Resource Planning (ERP), CAD, and Manufacturing Execution Systems (MES) to streamline operations.

- Service companies have adopted IT solutions at a later stage, focusing on customer relationship management (CRM), data analytics, and process automation to enhance service delivery. The delay in IT adoption was not due to a lack of interest but rather a consequence of technological development timelines.

IT Portfolio in Manufacturing Companies

In the realm of information technology, businesses require specialized software solutions tailored to their operational needs. These solutions are often categorized as vertical solutions, a term used to describe software systems designed to serve a particular industry by addressing its unique requirements.

Example

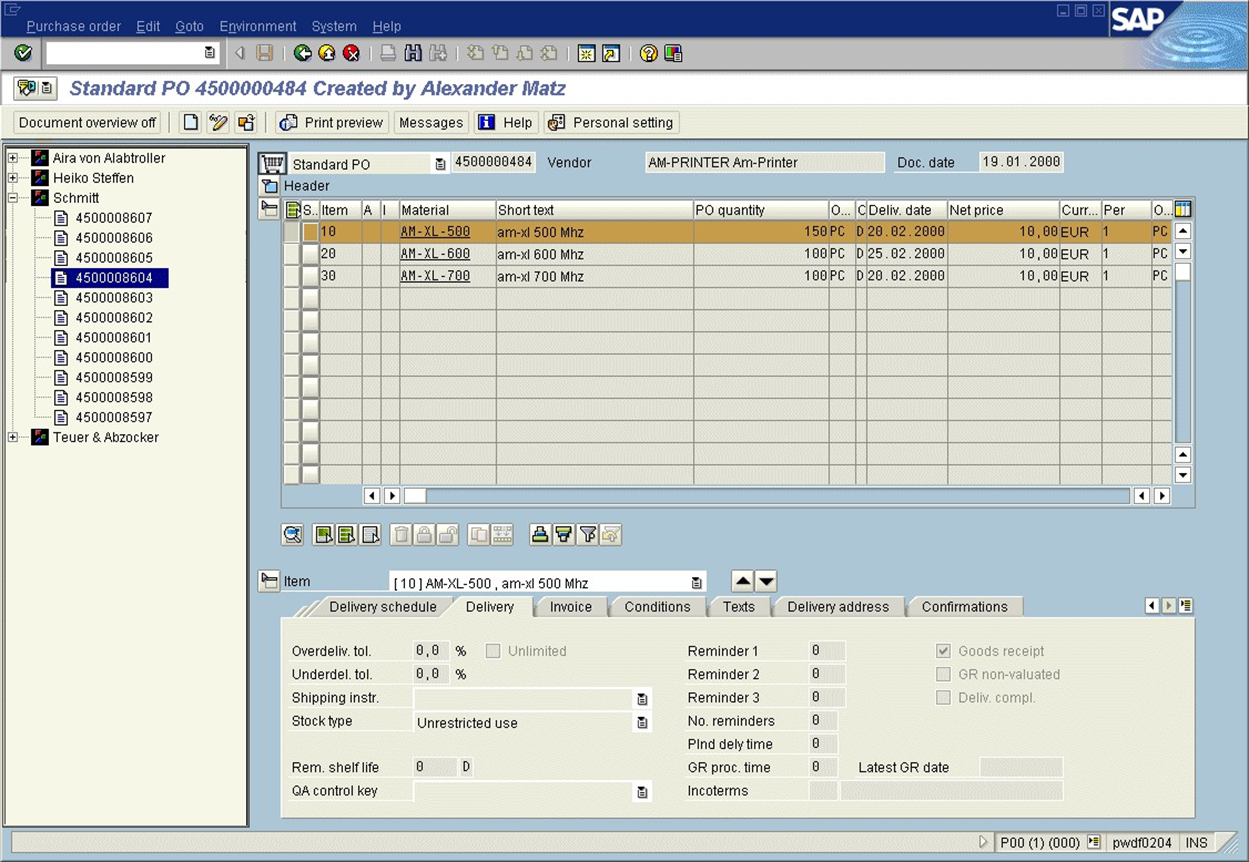

For example, large enterprise software providers like SAP offer a range of vertical solutions tailored for different industries such as finance, manufacturing, and logistics.

Each vertical solution is structured to accommodate the specific workflows, regulations, and business processes relevant to its respective industry.

The distinction between industries, particularly between manufacturing and services, is crucial when considering IT system design and implementation. Manufacturing companies requires robust enterprise resource planning (ERP) systems that manage supply chain operations, production schedules, and inventory tracking. Service-based companies, on the other hand, operate within an intangible framework, necessitating different IT architectures to manage customer relations, appointment scheduling, and digital service delivery.

ERP Systems and Parameterization

A key component of IT infrastructure in manufacturing is the ERP system. ERP (Enterprise Resource Planning) refers to integrated software platforms that manage core business processes such as accounting, procurement, production, and distribution. SAP, Oracle, and Microsoft Dynamics are some of the most well-known ERP providers, each offering configurable software packages that businesses can tailor to their specific needs.

ERP systems are not developed from scratch for each company but instead come as pre-packaged solutions that can be parameterized. This means that instead of rewriting code, companies configure ERP systems by setting values to pre-defined parameters. This approach allows businesses to adapt software without extensive coding, making implementation faster and more scalable.

For example, if a company produces 20 different products, an ERP system will include a parameter defining the total number of product categories. The parameter-based configuration ensures flexibility and adaptability, as companies can modify these settings through a GUI without altering the core software code.

Setting up and customizing ERP systems, which involve thousands of parameters, requires expertise. Business analysts are crucial in ERP implementation, analyzing workflows, defining requirements, and configuring parameters. They undergo extensive training to understand ERP systems and ensure proper implementation.

While ERP parameterization is not technically complex, it demands deep knowledge of business operations. Business analysts must identify parameter dependencies to avoid inconsistencies. For example, an inventory threshold might affect production scheduling, requiring careful coordination.

Configuring ERP systems, though repetitive, offers insights into corporate structures and decision-making. Professionals in this field gain expertise in IT systems and organizational management, making it a strategic career for those interested in enterprise software solutions and business process optimization.

The Functional Architecture of ERP Systems

ERP systems typically encompass three major functional portfolios:

-

Administrative Portfolio – This includes finance, accounting, human resources, and compliance management. The administrative portfolio remains largely the same across both manufacturing and service industries, as financial management principles are consistent across different business sectors.

-

Operational Portfolio – This is where the distinction between manufacturing and services becomes evident. In manufacturing, the operational portfolio includes production planning, supply chain management, and warehouse logistics. In service industries, the operational portfolio is focused on customer relationship management, scheduling, and service delivery coordination.

-

Executive Portfolio – This layer is developed after the operational portfolio since it relies on data generated from business operations. The executive portfolio includes business intelligence (BI) tools, dashboards, and strategic decision-making support systems.

Historically, IT solutions were developed in isolation, with different systems managing finance, production, and logistics separately. Over time, the need for integration became evident, leading to the development of ERP systems that unify business processes into a single, cohesive platform. This integration trend continues today, with modern ERP solutions offering cloud-based and AI-driven functionalities to enhance decision-making and process automation.